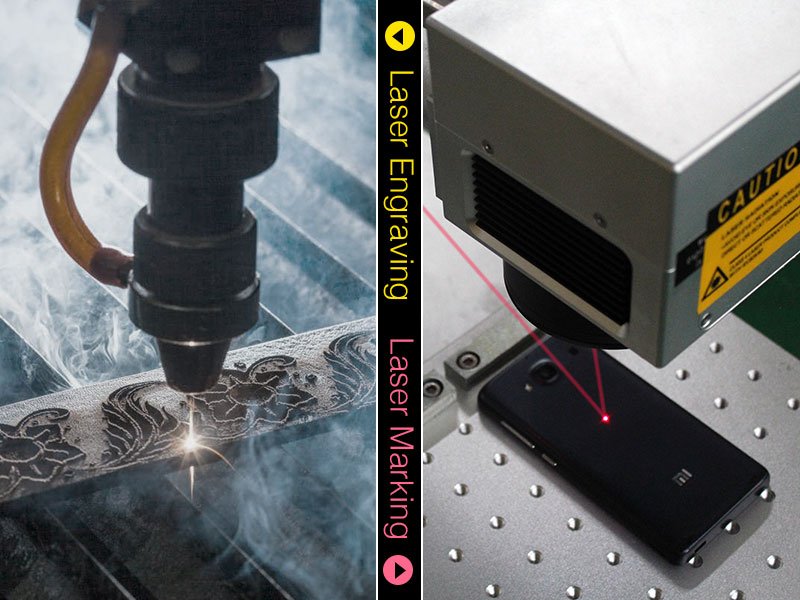

Surface engraving on tools has been a concept that predates the medieval era. People of ancient culture or early man, in particular, carved his writing on stones for posterity and further used it to trace the knowledge about something important. Of course, with time, as everything got evolved, this trait of human beings also got revolutionized to modern techniques. These days, the technique is usually practiced on the surface of the products for people to find it attractive or gather information about the same. Laser marking or engraving has long been a fancy concept that has now become a protocol for manufacturers and vendors to use on products.

Some serial numbers or barcodes become a necessity on the products for display as they reveal the details about them and are needed for internal tracking as well. Hence laser engraving has become more of a regulation that is mandated across all product and manufacturing companies. The predominant method to accomplish surface engraving has been through laser, and that technique is used rampantly in almost every product company nowadays.

Before we delve deeper into the facets of laser engraving, we will have a roundabout explanation of this technique as to what it is used for and what are the types it entails.

Contents

What is a laser engraving machine?

Sometimes when a product is designed and manufactured, cropping or cutting the metal on the same requires extreme precision and perfection. They spruce up the look of the product and this extra fine-tuning on the surface helps them to mold it or weld it according to their choice.

Sometimes if you want to carve something on the product like protocols to be followed for its use or expiry details, the only way to do it is by laser engraving. Before the advent of this technology, people used burins or hard tools to engrave the systems. Now that we have been able to do it in a more flexible way through laser implementation, the process has become easier and effective in all dimensions.

It is basically the heat from the laser beams which engraves the surface and molds it to its appropriate use. The beams or rays from these lasers modify the specific parts of the products to bring them into a desirable shape. It vaporizes and heats up the layer thereby engraving the product to precision without any hiccups. One basic advantage that could be accounted as a benefit is that the surface of the metal does not get spoilt or damaged even to bits in the process.

How does the machine work?

These machines have a controller which directs the path of the beam on its reflection. These controllers determine and guard the speed of the beam along with the intensity and distance it is thrust upon. The spread area of the beam has to be monitored for it to be perfected to the appropriate form.

There is a purported use of laser optics which also decides the X-Y dimension and the axis it has to trace. Sometimes the beams traverse above the whole body of the product, and sometimes the product moves around while the laser beam is static.

There is software designed to target the signals and beams to a particular direction, which also effectively controls its intensity and speed. Laser engraving machines widens its usage across all kind of products with base metals including wood, plastic, or glasses. They are also abundantly used on guns, jewellery, cutting machines, or hydraulics and electric metals, etc.

The applications of laser marking have been extended across various fields and nothing seems to be excluded in its leverage. The best innovation companies in laser marking that havebeen rising above ranks and gaining popularity are so many in numbers. The most prominent one is LASIT which has been a pioneer in this field and has almost progressed its usage encompassing all its latest innovations in that area. It has been serving different clients pertaining to different fields and has become the inevitable solution for laser marking technique in almost any product that has been manufactured recently. It adheres to the principles and guidelines of the clients and places their needs above any regulations and restrictions of that technique itself.

Conclusion:

Laser engraving or marking has become a separate professional stream with expanded features covering almost all possible product lines. They have also become a necessity in today’s world where manufacturers place a lot of significance on this aspect of product-making.