In the dynamic landscape of workplace safety, understanding the significance of Material Safety Data Sheets (MSDS) is paramount. This comprehensive article delves into the various facets of why MSDS Certificate is required, shedding light on its pivotal role in ensuring the well-being of individuals in different environments.

Contents

Why MSDS Required in Workplaces

Material Safety Data Sheets are indispensable in workplaces for several reasons. They provide detailed information on the properties of chemicals, ensuring that employees and employers alike are well-informed about potential hazards. From manufacturing plants to offices, having access to MSDS enhances safety protocols and minimizes the risk of accidents.

Ensuring Compliance with Regulations

One compelling reason why MSDS is required is the legal obligation. Many regulatory bodies mandate organizations to maintain updated MSDS for the chemicals they use. This compliance not only safeguards the workforce but also shields companies from legal repercussions. Understanding and adhering to these regulations is crucial for any responsible business entity.

Emergency Preparedness and Response

Imagine a scenario where a chemical spill occurs in a laboratory or an industrial setting. The availability of MSDS becomes instrumental in emergency situations. It provides immediate guidance on how to handle and contain the spill, protecting individuals and the environment from further harm. In essence, MSDS is a key component of any effective emergency preparedness plan.

Facilitating Safe Transportation

For industries involved in the transportation of hazardous materials, MSDS is a prerequisite. It ensures that those handling and transporting these materials are aware of the potential risks and necessary precautions. This not only protects the personnel involved but also the general public and the environment.

Promoting Occupational Health

Occupational health is a top priority in any workplace. Incorporating MSDS into occupational health programs ensures that employees are aware of the potential health risks associated with the substances they work with. This knowledge empowers individuals to take preventive measures, fostering a healthier and safer work environment.

The Importance of Why MSDS Required

Creating a Culture of Safety

Having MSDS readily available creates a culture of safety within an organization. It demonstrates a commitment to the well-being of employees and sets a standard for responsible practices. Employees are more likely to engage in safe work habits when they know their employer prioritizes their safety through initiatives like maintaining MSDS.

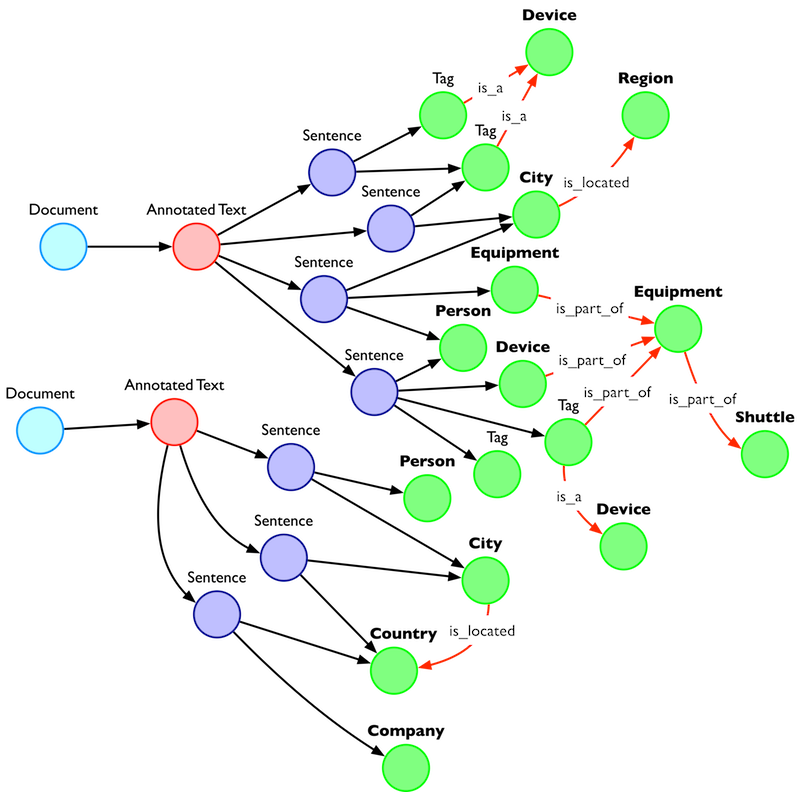

Enhancing Risk Management Strategies

Risk management is an integral aspect of any business operation. Understanding why MSDS is required enables organizations to integrate these data sheets into their risk management strategies effectively. This proactive approach minimizes the potential for accidents and ensures swift and informed responses when unforeseen events occur.

Fostering Trust and Confidence

External stakeholders, including clients, partners, and regulatory bodies, often assess an organization’s commitment to safety. By showcasing a robust MSDS program, companies build trust and confidence. This not only benefits their reputation but also opens doors to collaborations and opportunities.

Why MSDS Required: Addressing Common Questions

1. Are MSDS Always Required?

Yes, MSDS is generally required for substances or mixtures classified as hazardous. Regulatory bodies mandate their availability to ensure safety in workplaces dealing with such materials.

2. What Information is Included in an MSDS?

An MSDS typically includes information on the chemical’s properties, potential hazards, safe usage guidelines, first aid measures, and proper storage and disposal procedures.

3. How Often Should MSDS be Updated?

MSDS should be updated whenever there is new information about the hazards or safe use of a chemical. Regular reviews, at least annually, are recommended to ensure accuracy.

4. Can Digital MSDS be Used?

Yes, many organizations opt for digital MSDS, provided they meet regulatory requirements. Digital formats offer convenience, accessibility, and ease of updates.

5. Who is Responsible for Providing MSDS?

The responsibility lies with the manufacturer or importer of the chemical product. However, employers are required to ensure that MSDS is readily available to employees.

6. What Penalties Exist for Non-Compliance?

Penalties for non-compliance with MSDS regulations vary by jurisdiction but can include fines, legal action, and, in extreme cases, business closure.

Conclusion

In conclusion, understanding why MSDS is required is pivotal for fostering a safe and compliant work environment. From legal obligations to emergency preparedness, the multifaceted role of MSDS cannot be overstated. Implementing robust MSDS programs not only ensures regulatory compliance but also contributes to a culture of safety, risk management, and trust within organizations.